Why Is 5000 Bags Minimum for Flat Bottom Coffee Bag in China Factory?

There are most households around the world, who are like coffee. Coffee packaging isn’t just a formality, it’s a crucial player in preserving the essence of every coffee. More coffee shops, brands and manufacturers hope to increase coffee sales by customized their brand on coffee bag packaging. When they inquiry for Chinese suppliers about customized coffee bag packaging, coffee bags supplier will tell them the minimum order quantity 5,000 pieces. It makes them have to buy locally or use traditional labeling methods to have their own logo and design on the coffee packaging. Therefore, we solve the mystery to uncover the intricacies behind the 5000 bags minimum for flat bottom coffee bags in Chinese factories. It’s not an arbitrary number; it’s a strategic decision intertwined with the dynamics of production, cost efficiency, and maintaining consistent quality.

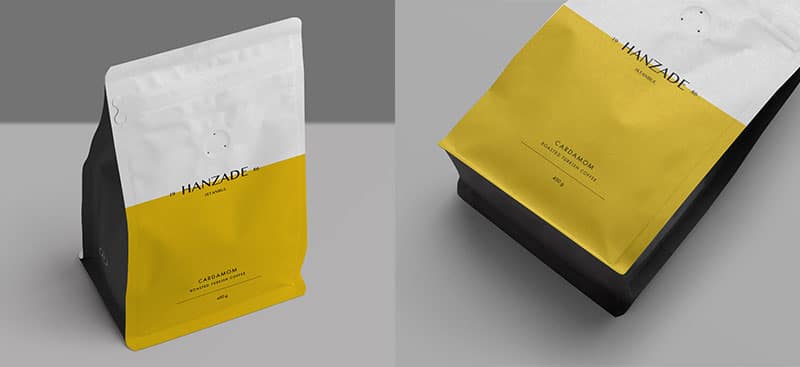

Understanding Flat Bottom Coffee Bags

Flat bottom coffee bags aren’t your run-of-the-mill pouches. These bags don’t just cradle your coffee; they showcase it. With stable design and ample space for branding, flat bottom bags strike the perfect balance between aesthetics and functionality. Their unique design not only catches the eye on the shelf but also ensures your coffee stays as fresh as the day it was roasted.

Design and Features of Flat Bottom Coffee Bags

The flat bottom design isn’t just for show. It provides stability, preventing your precious beans from rolling away. The generous surface area allows for creative branding, making your product stand out in a sea of options

Benefits of Using Flat Bottom Bags for Packaging Coffee

Why choose flat bottom bags over traditional packaging? Well, the benefits are aplenty—enhanced shelf appeal, space for informative labels, and the assurance that your coffee stays put, unaffected by external factors.

Market Demand for Flat Bottom Bags in the Coffee Industry

As coffee lovers become more discerning, the market demands packaging that reflects the quality of the product. Flat bottom bags, with their combination of style and practicality, have become the go-to choice for both producers and consumers.

Manufacturing Flexible Packaging Bags Process

The manufacturing process of flat bottom coffee bags in Chinese factories involves a meticulous series of steps, thus ensuring the highest quality and functionality of the final product. Moreover, understanding this process provides insights into why a Minimum Order Quantity (MOQ) of 5000 bags is often implemented.

Design and Prepress

The process begins with the design phase, where coffee brands collaborate with the factory to create custom artwork and branding for their bags. Once finalized, the artwork undergoes prepress preparation, including color separation and plate making, ensuring accurate and vibrant printing results.

Material Selection and Preparation

High-quality materials, such as laminated films, are carefully chosen to meet the specific requirements of flat bottom coffee bags. These materials undergo precision cutting and preparation to ensure consistent dimensions and optimal performance during the manufacturing process.

Printing and Laminating

Advanced printing techniques, such as rotogravure or flexographic printing, are employed to transfer the artwork onto the prepared films. Multiple layers of film are then laminated together to create a durable and barrier-resistant structure, ensuring the coffee’s freshness and aroma are preserved.

Bag Making

Felxible packaging manufacturer cust and shap the laminated films into flat bottom coffee bags using specialized bag-making equipment. This process includes precise folding, sealing, and cutting to create the distinctive flat bottom shape that provides stability and ease of filling.

Quality Control and Packaging

Throughout the manufacturing process, strict quality control measures are in place to monitor parameters like print registration, seal strength, and overall bag integrity. Once the bags pass rigorous inspections, factories carefully package and prepare for shipment to coffee brands and retailers.

The manufacturing process of flat bottom coffee bags in Chinese factories involves multiple stages, including design, material selection, printing, bag making, and quality control. The 5000 bags MOQ influences the process by optimizing production efficiency, ensuring stable supply chains, and enabling cost-effective customization options. According to Soaraway’s 18 years of production experience, the production time and labor required to produce 1,000 and 5,000 units are the same. Ordering in bulk allows factories to optimize these factors, resulting in cost-effective production. By comprehending the intricacies of this process and the rationale behind the MOQ, coffee brands and retailers can appreciate the value it brings in terms of quality, efficiency, and affordability of flat bottom coffee bags.

Cost Factors

Coffee brands and retailers may confuse the MOQ 5000 pieces set by China manufacturers for flat bottom coffee bags. Therefore, understanding the cost factors behind this decision sheds light on the economic considerations involved in the production process.

Material Sourcing and Procurement

China manufacturers aim to source high-quality materials at competitive prices. Bulk material purchases help achieve cost savings, as suppliers often offer better pricing for larger quantities. Setting the MOQ at 5000 pieces facilitates efficient material procurement and cost optimization.

Production Efficiency

Flat bottom coffee bags undergo printing, laminating, and bag assembly, involving complex manufacturing processes. China manufacturers prioritize efficient production to minimize costs, achieved through a higher MOQ. This maximizes production line utilization, reduces setup time, and lowers production costs per unit.

Setup Costs

Each production run incurs certain setup costs, such as equipment calibration, material preparation, and labor allocation. With a higher MOQ, China manufacturers can spread these setup costs across a larger number of units, reducing the per-unit cost and making the production economically viable.

Customization and Printing

Coffee brands often require customized designs and branding on their packaging. Customization involves additional setup and printing costs. By setting a higher MOQ, China manufacturers can accommodate these customization requests economically, as these costs can be amortized over a larger production volume.

Shipping and Logistics

Flat bottom coffee bags are produced and shipped in bulk. Setting a higher MOQ allows for more efficient logistical planning, consolidating shipments and reducing transportation costs per unit. This benefits both the manufacturer and the customer, ensuring competitive pricing for the final product.

While a MOQ of 5000 pieces may seem high, it reflects the cost dynamics and economies of scale in the manufacturing process. China flexible packaging manufacturers carefully consider these factors to offer competitive pricing while maintaining profitability. Understanding these cost factors helps coffee brands and retailers appreciate the rationale behind the MOQ and the value it brings in terms of cost efficiency and product affordability.

Quality Assurance and Consistency

Maintaining quality standards is paramount in the competitive coffee market. A higher MOQ ensures consistency in production, reducing the risk of variations in product quality. It’s a strategic move to meet the expectations of discerning consumers. Consistency in product quality is crucial for coffee brands and retailers who strive to provide an exceptional coffee experience to their customers. One effective way to achieve and maintain this consistency is by setting a higher Minimum Order Quantity (MOQ) for flat bottom coffee bags. While it may seem counterintuitive, a higher MOQ holds great potential in ensuring unwavering product quality from batch to batch.

By implementing a higher MOQ for flat bottom coffee bags, manufacturers can optimize their production processes and enhance quality control measures. First and foremost, a higher MOQ allows manufacturers to fine-tune their production lines specifically for coffee bag manufacturing. This optimization ensures that each step of the process, from material selection to bag construction, is carefully executed to meet the highest standards.

Moreover, a higher MOQ enables manufacturers to invest in advanced machinery and technologies tailored for coffee bag production. This investment contributes to greater precision, consistency, and efficiency in manufacturing, resulting in coffee bags that meet the exact specifications and quality requirements batch after batch.

Additionally, a higher MOQ encourages manufacturers to implement rigorous quality control protocols. With larger production volumes, manufacturers can dedicate more time and resources to comprehensive testing and inspection of each batch of flat bottom coffee bags. This meticulous approach helps identify any potential issues or defects early on, ensuring that only the highest quality bags reach the market.

Market Trends and Competitiveness

The market trends and competitiveness surrounding the Minimum Order Quantity (MOQ) of 5000 bags for flat bottom coffee bags reflect the dynamic landscape of the coffee packaging industry. Understanding these trends provides valuable insights into the advantages and competitiveness associated with this MOQ requirement.

Growing Demand for Specialty Coffee

The coffee industry has witnessed a significant rise in the demand for specialty coffees, offering unique flavors and experiences. As a result, coffee brands are increasingly focused on differentiating themselves through premium packaging that highlights their quality and craftsmanship. The MOQ of 5000 bags allows brands to access custom-designed, high-quality flat bottom coffee bags that align with the specialty coffee market’s requirements.

Economies of Scale

Setting the MOQ at 5000 bags enables manufacturers to leverage economies of scale. With larger production volumes, manufacturers can optimize their production processes, reduce per-unit costs, and offer competitive pricing. This cost advantage benefits both the manufacturers and the coffee brands, allowing them to deliver quality packaging while maintaining profitability.

Customization and Branding Opportunities

Flat bottom coffee bags provide ample space for branding and customization, allowing coffee brands to create a unique identity and connect with their target market. The MOQ of 5000 bags facilitates cost-effective customization options, such as custom artwork, logos, and color schemes. This enhances brand visibility and customer engagement, giving brands a competitive edge in the market.

Sustainability and Eco-Friendly Packaging

The market trends indicate a growing emphasis on sustainable packaging solutions. Flat bottom coffee bags can be manufactured using eco-friendly materials and processes that reduce environmental impact. With the MOQ of 5000 bags, manufacturers have the ability to invest in sustainable practices and materials, meeting the demands of environmentally conscious coffee brands and consumers.

Supply Chain Efficiency

A minimum order quantity of 5000 bags promotes efficient supply chain management. Coffee brands and retailers can benefit from reduced lead times, streamlined logistics, and stable inventory levels. The ability to access a larger quantity of flat bottom coffee bags ensures a continuous supply, minimizing the risk of stockouts and maintaining consistent product availability.

Competitive Advantage in Retail

Flat bottom coffee bags offer several advantages for retail environments. Their stability, shelf presence, and resealable features contribute to better product visibility, ease of storage, and prolonged freshness. The MOQ of 5000 bags allows coffee brands to secure a sufficient supply of these retail-friendly packaging solutions, positioning themselves competitively on store shelves.

Conclusion

In conclusion, the 5000 bags minimum for flat bottom coffee bags in China factories reflects a strategic approach to production, customization, and market demands. Additionally, it enables efficient manufacturing processes, cost optimization, customization opportunities, and supply chain efficiency. Moreover, it aligns with sustainability trends. Ultimately, by adhering to this MOQ, China factories can effectively deliver high-quality packaging that meets the needs of coffee brands and delights discerning consumers worldwide.